Exhibition Day

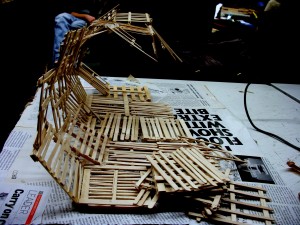

Posted: March 13, 2011 Filed under: Uncategorized Leave a commentThe Final Structure.

Puzzles with Pallets

Posted: February 24, 2011 Filed under: Uncategorized Leave a commentOne day to go, there is a light at the end of the tunnel!

We set the alarms early once again and headed straight to the studio to make some final adjustments to finish off our (now rather large) structure, creating yet more saw dust, noise and lovely woody mess. I think it is safe to say, team timber have definitely made their mark in the undergrad studio.

Then the disassembly began, as we figured out how on earth we were going to get all our bits and pieces into the back of Howard’s van and down to the Moor, ready for the final installation on Friday. We broke the sections down into chunks of 2 and 3 pallets and played a bit of ‘to-me-to-you’ as we carefully moved all the pieces through the doors, round some bends and eventually out of Crookesmoor and onto the back of the van, taking great care not to damage our darling ‘fillets.’ We were anxious that the joints would weaken if we put them under too much stress, but after a bit of rearranging we managed to puzzle them together to (almost) fit in one load, along with all the exhibition stands and other equipment… we were quite impressed with our space efficiency skills!

Now all ready and set for the morning, time to rest our exhausted bodies ready for the big day tomorrow.

People of the Moor, please prepare yourselves for the TEAM TIMBER TAKEOVER!

The Next Day….

Posted: February 23, 2011 Filed under: Uncategorized 1 CommentWell it’s still standing up which is a huge bonus! Howard came to have another look this morning and has given us the following suggestions:

- Putting a second layer of floorboard on the joints but on the other side so that both sides look the same

- Putting a layer of slats, taken from other pallets, over the fillets to give a ‘second skin’ to the interior of the structure

- Maybe putting a seat within the structure to give it more than one use

As a group we are also considering whether we should continue from here to develop the wave idea that can be seen in earlier photos of our model, or to keep the symmetry that we currently have and have it devolving and you walk through it, with there being less pallets each time.

Comments and advice would be very much appreciated at this time so please feel free to come over to us in the studio and tell us what you think. You can’t miss us because we’re working next to the giant timber circle made out of pallets!

If you can’t make it over then please leave a comment on here! We would love to get some feedback from someone other than Howard (although we really do appreciate your feedback!)

Thanks and love from Team Timber

What? How? When? Who?

Posted: February 23, 2011 Filed under: Uncategorized 1 CommentSo, time for the explanation…

The day began with a lot of frustration as the tutors ripped holes into our design and our plans for the day. However this only acted to encourage us and we were more determined than ever to succeed!

We started by making the base for the circle. We decided that using the floorboards for the joint was still a good idea as it was a strong material that we have a good supply of, although we have abandoned the previous design. We are now cutting a triangle out of the floorboards, and using thin pieces of timber, screwed to the floorboards to attach them to the pallets. We also created some supports on the exterior of the pallets to give it extra strength and make sure that the overall stability is not relying solely on the floorboards, or fillets as we keep calling them.

We fixed the bast pieces together and got it standing up. Now for the next layer…

Because we didn’t want there to be huge stresses on the materials while we were constructing the circle we decided to lie it down and construct it like this.

The tutors had doubts that we would be able to lift it up after we had built it but we carried on regardless. By now we pretty much knew what we were doing so the progress from here was relatively quick.

We attached the next two pallets and finally the two pallets that would make up the roof. Everything was fine when it was resting on its side but now was the moment of truth. We had to lift the entire structure to its upright position. Luckily almost all the group members were there so we managed it, put all the supports in place and there it stood, in all its glory.

Team Timber – 1 Tutors – 0

Obviously there was a lot of excitement amongst the group, but no one seemed quite as excited as Andy…

WE DID IT.

Posted: February 23, 2011 Filed under: Uncategorized 1 CommentIts been a long day so a post tomorrow will explain how we did it but for now simply marvel at the fact we did it!

Blue Monday

Posted: February 23, 2011 Filed under: Uncategorized 1 CommentTerrible News…. We arrived at Crookesmoor today only to find that the joints we made on Friday are falling apart. Unfortunately, over the weekend, the ash has dried and shrunk and is not holding the laminate together any more, making the joints useless. Back to the drawing board as they say!

However, the silver lining to this dark cloud is that we are allowed to use screws. Which means no more messing around with ash and that the structure should hopefully be a lot stronger.

Also have to say a big thank you to the third years who helped us to realise that having a complete circle as the first element of the wave would make the whole structure much stronger and mean that we might actually be able to build it.

The plan now is to come back tomorrow ready to build the complete circle and take it from there. Time will tell.

First Attempts

Posted: February 22, 2011 Filed under: Uncategorized 1 CommentSo today we actually had to build this structure, or at least make a good start. I think we all knew it was going to be a long day…

We began by discussing how we could get the structure to stand up. Our engineers came up with a brilliant joint made from the floorboards that B3 no longer needed and ash to act as dowels to join it all together. The joint is made of 4 pieces of the floorboard, two placed together to make a large triangle with two pieces either side to keep it together and make it stronger. We then drilled holes through the pieces and hammered ash through to keep it all together.

The joint will sit in compression, and should stop the wave from collapsing due to the weight of the pallets on the top of it.

While the first test joint was being completed Ed and I decided to go explore in a skip just around the corner from Crookesmoor to see if there were any floorboards, as we are clearly going to need lots to do this joint! Unfortunately the journey was not successful but not a complete failure either! Pete Williams was having some materials delivered and we managed to acquire three pallets in pretty good condition from the driver of the night freight truck. Thank you!

Next we used the joints to connect pallets together. This was a complicated process and took a while as we were essentially designing the joint as we made it. We had a production line going for a bit making the joint but this was soon shut down due to the fact that we didn’t know if the angles of all the joints would be the same. At least we didn’t waste any floorboards!

We made 6 of these joints in total and managed to join 4 pallets together in pairs of two. A productive day and hopefully we can push this forward next week.

The day wasn’t all work though. Here are some of the other things we got up to:

The Timber-Off

Posted: February 16, 2011 Filed under: Uncategorized Leave a commentThe day had come to get busy in the studio, finalize designs and be ready to present our proposal to the rest of the year by 3.30 that afternoon. Up against 3 other strong Timber groups, the heat was on to produce a design strong enough to win the votes, getting the chance to develop and proceed to build our ‘place for conversation’ down at the Moor.

Lots of chatting, drawing, constructing, gluing, thinking, sticking and a fire alarm went down.

After raiding every cafe in the Broomhill/Crooksmoor perimeter for some drink stirrers, (last-minute modeling materials) we began the difficult procedure of assembling our model. Our lovely pallets were proving to be slightly difficult, preferring to stick themselves to our hands rather than stick to each other… Brilliant.

Fingers now permanently stuck together, a few frustrated remarks later, we decided the super glue was anything other than super so went on the mission of finding an alternative sticking method. Glue guns seemed to be particularly popular among the studio and after every effort to hunt one down we, (or Nasr even) resorted to running down to the Hardware store to buy one ourselves. Problem solved (thank you Nasr,) the model lives on.

Andy got his Engineers hat on and did a bit of cardboard construction of the joints to convince everybody the structure WILL stand up, and the rest of us got going with sketches/collages/sketch up drawings to finish everything off. It all looked something like this:

…And did we win?

Ofcourse we did. Bring on those Pallets.